WHY FOTON

FOTON ZF, SINCE 2008

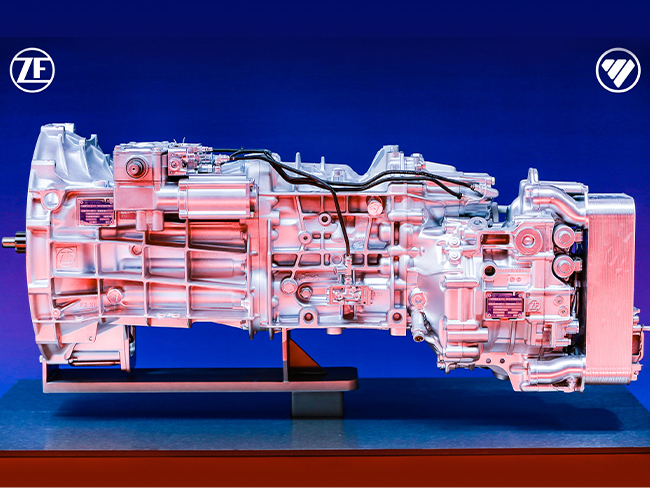

The long cooperation between FOTON and ZF has started since 2008. Both parties have been continually seeking opportunities to further deepen cooperation in terms of transmission system technology. With mutual recognition of excellent market potential for automated commercial vehicles, at the end of 2016, FOTON and ZF established two joint ventures in China, which are known as ZF Foton HCV Automated Transmissions (Jiaxing) Co., Ltd. and Foton ZF LCV Automated Transmissions (Jiaxing) Co., Ltd.

LEADING TECHNOLOGY COOPERATION

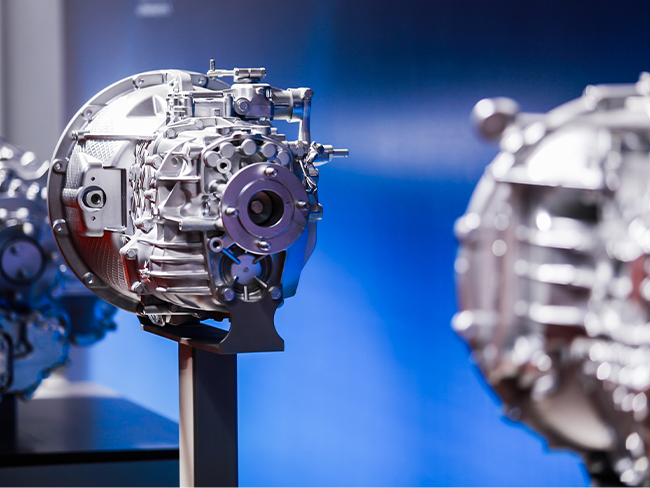

The joint venture has made automatic transmission a core strategy and has launched a full range of automatic transmission products. The heavy-duty automatic transmission, namely ZF’s second-generation TraXon AMT gearbox, is about to be mass-produced by FOTON & ZF joint venture company, further improving fuel economy and driving comfort.

99.7% EFFICIENCY

FOTON has taken commercial automation and digitalization as a central position in corporate strategy, aiming to making fleet management for trucks more efficient than ever before, and leading forward to the commercial vehicle mobility and intelligence.

BFDA: GERMANY MANUFACTURING STANDARD

On February 18th, 2012, Foton Motor established the joint venture of Beijing Foton Daimler Automotive Co., Ltd.(BFDA) with Daimler AG, the world’s largest commercial vehicle manufacturer. Foton Daimler Automotive(BFDA) operates under single brand FOTON AUMAN medium and heavy-duty trucks, engaging in AUMAN designing, manufacturing and distribution around the world. Since the first AUMAN produced by BFDA rolled off the production line, a total of 1,000,000+ units have been produced and sold.

BFDA has the full life cycle development and operation capabilities of heavy trucks, including research and development, verification, production, manufacturing, sales, and service. BFDA’s global digital super truck factory adopts the European truck manufacturing standards and the German lean manufacturing system TOS+. Following the concept of “zero emission, contactless, automation”, it upgrades and introduces automation, digitalization, and intelligence technologies to create a world-class modern factory and automated production line. It has four major processes: stamping, welding, painting, and assembly. The automation level of the production line is over 60%.

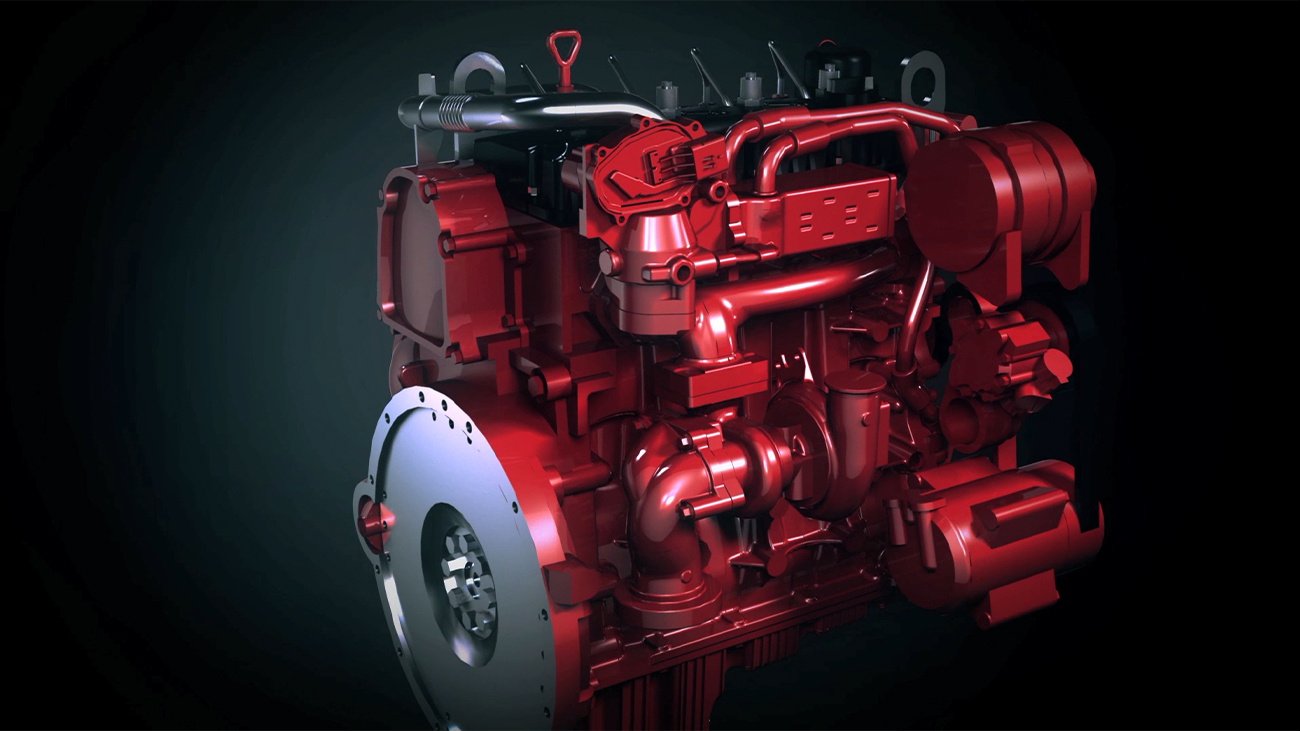

AUMAN integrates Foton Cummins engines, Foton ZF TraXon with FOTON axles, creating a highly integrated and technologically advanced powertrain integration SuperPowerTrain. It achieves a holistic integration and coordination of software and hardware, making the logistics transportation equipment more fuel-efficient, more efficient, and more competitive. The engineering vehicles are more reliable, more productive, and more profitable.

AUMAN has connects to the IOV system of SuperFleet, which based on GPS and BDS (BeiDou Navigation Satellite System), to provide services such as vehicle positioning, vehicle tracking, trajectory playback, etc., and to keep track of vehicle dynamics. It enables remote control of vehicle locking, vehicle start-up, temperature setting, etc. through smart devices, achieving remote operation of vehicles. It comprehensively monitors the real-time usage, vehicle diagnosis, tracking evaluation, vehicle maintenance, refueling records, service provider inquiry, service dispatching, customer service hotline, etc., providing intimate service and worry-free maintenance. It analyzes the driving behaviors such as speeding, engine over-revving, sudden acceleration, sudden deceleration, coasting in neutral, etc., effectively reducing the risk of failure and ensuring more reliable and safe protection.